Market Based Solutions

Virginia Palacios is a Senior Research Analyst at Environmental Defense Fund. In her current role, Palacios provides technical expertise on scientific and regulatory concepts related to local distribution pipeline safety, lost and unaccounted for gas, and quantification of methane emissions from local distribution system pipelines.

For natural gas utilities, advanced leak detection technologies and data analytics are changing the landscape. This is making it more cost effective than ever before to use leak flow rate data to prioritize resource allocation.

The door is now open for utilities to integrate leak quantification into their operations and employ the resulting data to improve the economic and environmental efficiency of capital investment projects.

The framework for capturing these benefits is described in our white paper, Integrating Leak Quantification into Natural Gas Utility Operations. It explains how utilities can use leak flow rate data to make decisions about capital investments, while taking safety considerations into account.

Notably, we provide data detailing the results of our collaboration with New Jersey's largest natural gas utility, Public Service Electric & Gas. Using leak flow rate data allowed the gas company to achieve an eighty-three percent reduction in leakage early on in their pipeline replacement program. It replaced one-third fewer miles of gas lines than would have been needed to achieve the same result under a business-as-usual scenario.

Information on the size of leaks can help utilities verify and validate the need for leak repair and pipe replacement programs. That information will allow regulatory agencies to better assess the need for such efforts.

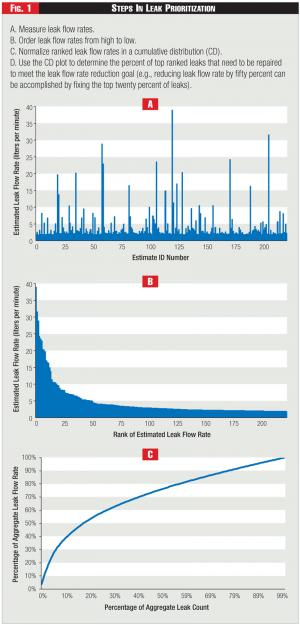

Figure 1 - Steps In Leak Prioritization

Figure 1 - Steps In Leak Prioritization

Leak quantification can improve project management. It allows utilities and utility commissions to evaluate leak repair and pipeline replacement programs by considering the reduction in volumes of leaked gas. The white paper describes the implications of integrating leak quantification into regular utility operations in detail. It explores frameworks for implementation based on current utility practices.

After a series of natural gas distribution pipeline explosions, the Pipeline and Hazardous Materials Safety Administration (PHMSA) issued a "Call to Action" to state pipeline regulatory agencies, pipeline operators and technical experts in 2011.

Recognizing the safety risks associated with cast iron gas mains, PHMSA urged state agencies to facilitate accelerated pipeline replacement programs for cast iron and other high-risk pipeline segments.

Accelerated pipeline replacement programs, while necessary from a safety standpoint, also carry significant ratepayer and environmental implications. Pipeline replacement can cost between nine hundred thousand and three million dollars per mile of pipe.

“The framework for capturing these benefits is described in our white paper, ‘Integrating Leak Quantification into Natural Gas Utility Operations.’” - Virginia Palacios

“The framework for capturing these benefits is described in our white paper, ‘Integrating Leak Quantification into Natural Gas Utility Operations.’” - Virginia Palacios

Utilities across the country are looking to replace many, if not most, of the seventy thousand miles of leak-prone distribution pipes still in operation in the U.S. The timeline extends over the next two decades, at an estimated cost of over two hundred billion dollars.

The size of these investments underscores the need to thoughtfully design and execute pipeline replacement programs. After hazard assessment data is considered, leak flow rate data provides valuable information about a utility's gas infrastructure, which can aid in prioritizing leak repair and pipeline replacement. Using these data optimizes operating and capital expenditures.

Utility gas leaks present what is known as a "fat-tail" distribution, where a relatively small percentage of leaks is responsible for a disproportionately large percentage of lost gas. Advanced leak detection technology can identify the most hazardous and/or largest leaks, which can be prioritized for remediation.

Rather than finding and fixing leaks one at a time with a relatively flat temporal and spatial distribution, utilities and regulators can use leak survey information as the first step. Advanced analytics is a second step to prioritize remediation.

As shown in Figure 1 (A), the flow rate of leaks can vary significantly. When ranked from largest to smallest as shown in Figure 1 (B), the relative importance of different leaks is transparent and the relative contribution of each leak to overall leak flow rate is easily quantified in Figure 1 (C).

The cumulative distribution is created by integrating the ranked distribution in Figure 1 (B) from left to right. The first data point from the left on the X-axis in the CD plot is the leak determined to have the largest leak volume. The second point is the cumulative leak flow rate of the top two leaks, the third point is the sum of leak flow rates of the top three leaks, and so on.

Thus, the last data point is the sum of leak flow rates of all known leaks. This distribution is then normalized to one or to a hundred percent in Figure 1 (C). We can then readily consider the relative contribution of a certain number of leaks to the total system-wide leakage.

Many other utilities are using or exploring the use of advanced leak detection technologies and leak quantification methods. However, adoption of these technologies could be delayed as utilities seek approval from state regulators and, where necessary, address regulatory requirements premised on older leak detection methods.

Regulators, for their part, may be skeptical of advanced technologies until most utilities have adopted them. This logjam could soon be broken. The Pipeline and Hazardous Materials Safety Administration Distribution Integrity Management Program regulations not only allow for the use of leak flow rate data to improve integrity management, but underscore the need to do so. And some state regulators are starting to consider or require the use of advanced leak detection technology and leak quantification, so the opportunity for broader utility uptake is ripe.

Natural gas is made of methane, and methane is over eighty times more potent than carbon dioxide as a climate warming pollutant over the first twenty years it is emitted. When natural gas leaks into the atmosphere from utility infrastructure, customers pay the price and the environment is degraded.

But market based solutions like advanced leak detection technology and leak quantification, by addressing the methane leakage problem, save customers money and can help to realize the potential climate benefits of natural gas.

Working together, state regulators and utilities can use advanced leak detection technologies and leak quantification methodologies to improve both the economic and environmental efficiency of large capital expenditures directed at replacing pipeline and reducing the number and size of pipeline leaks.

Lead image: Gas Sampling Valve (GSV) Car for Leak Detection